- Home

- Home_de

- Products

- Downloads

- Forum

- Sales

- News

- Exhibitions

- Know how

- Building VP-2500D workingtable

- First installation

- VP-2500D 0402 placement test

- Mark detection demo

- Placing TQFP48 demo

- 0201 Placement

- BGA Alignment

- FAQ-Feeder-settings

- Soldering-FAQ

- Controller Upgrade V1 to V2

- How to upgrade to 19 slot nozzle changer

- First setup and placement job

- How to build Electronics

- For Makers

- Questions & Answers

- Software

- Repair Documents

- References

- Service

- Spare-Parts

- Videos

- Warranty

- Kompetenz

- Competence

- Cookie Policy

- Privacy Policy

- About

- PANDA-design-contest

The weekly news about vision based pnp machine

SMALLSMT PANDA BASIC Pick & Place machine delivered to our contest winner Markus and Sören from Germany

We have found 2 nice and smart developers to write an OpenPNP compatible firmware for our V3 controller. This makes our most modern entry-level machine compatible with open source PC

software.

If everything goes well, we will have a working system by the end of the year.

Thanks to Sören and Markus.

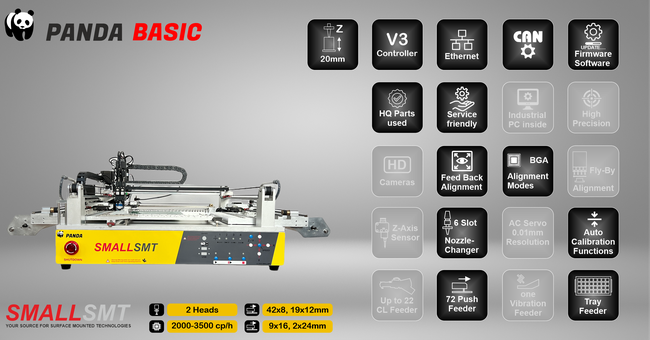

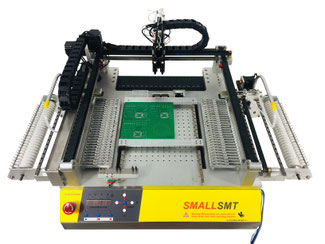

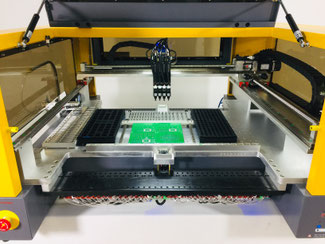

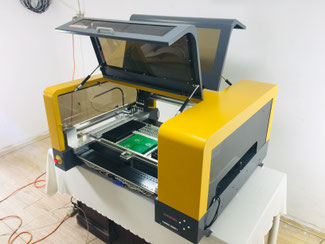

New PNP Machine SMALLSMT PANDA BASIC is shipping

Our new pick and place machine for the entry into SMD placement is called PANDA. This machine V2 is based on a standard XY system and is offered in 2 versions.

In the Basic version, an external Windows PC is required for control, which is connected to it via Ethernet and USB.

The PANDA PRO has cover, Z axis sensor and optional embedded industrial PC.

Both machines have 0.01mm X/Y resolution.

All feeders are created from durable aluminium rather than printed plastic. We have built in push feeders on 3 sides with 43x8mm, 19x 12mm, 9x 16mm and 2x24mm lines. Any tray can be mounted in

the work area and depending on the PCB size, other software defined feeders can also be set up.

3 cameras with 640x480mm resolution are installed.

The bottom cameras have different optics that can align components up to 30x30mm.

PCB size 300x300mm possible and if JEDEC Tray installed 300x170mm left.

And now the best news the prizes!

The PANDA BASIC variant will start at 3799usd

the PANDA PRO will cost 4399usd.

SMALLMT PANDA BASIC

SMALLSMT PANDA PRO

This version has optional embedded industrial I5 PC including windows 10 pro license.

Only external Monitor and air compressor needed to operate machine.

You can add to your network for file transfer and updates.

New Information Pages added!

We added some new information pages under menupoint Services in english.

Wir haben einige neue Informationsseiten unter Menupunkt Services_de in deutscher Sprache hinzugefügt

LED 0201 Placement Video released

Our placement machine Pecker shows the placement of 0201 LED. For this the new electronic feeder option is used and the components were aligned in fly by mode.

The video shows both results for the precise Full Alignment mode and the One Shot Fly By mode.

New Electrical CL Feeder Option released!

Electrical CL Feeder speed up the PNP processing because the need only 5ms feed time instead of >100ms. This makes a big difference if using 4/8 heads. The head don't need to wait over feeder to pickup same part to other heads. Second advantage is for very small parts you receive no part shaking during feed process.

Vision Placer V2.073 software released

New functions and bug fixes you find complete description in our software BLOG.

Don't forget to backup your SMT folder before applying update!

Vision Placer V2.069 software released

New functions and bug fixes you find complete description in our software BLOG.

Don't forget to backup your SMT folder before applying update!

Some news about new products

We have now added the Z-axis sensor to all 4 head machines. This is used to adjust the pick up height on the feeders. It simplifies this calibration enormously.

All models received some upgrades and finally we decided to build inline pick and place machines.

The first model is the VP-2800HP-CL64-4RCV which has built in 3 zone conveyor and SMEMA interface on both sides.

https://www.smallsmt.biz/vp2800hp-cl64-4rcv/

And finally we got our new 8 head machine RAPTOR up and running well.

I will post some informations in the next days.

We are still searching for a nice name the working title is RAPTOR it is placing 7200cp/h under vision alignment!

It has 3 Zone Conveyor System, 19 slot Nozzle Changer, SMEMA interfaces, embedded industrial PC and Air Supply!

Vision Placer V2.063 software released

New functions and bug fixes you find complete description in our software BLOG.

Don't forget to backup your SMT folder before applying update!

EXPOELECTRONICA 2021 in Moscow

EXPOELECTRONICA 2021 in Moscow

April 13 - 15, 2021

International exhibition of electronic components, modules and systems

https://www.eventseye.com/fairs/f-expoelectronica-835-1.html

PNP-Creator V1.05 B299 released!

Our new PNP-Creator job preparation softare is a real WSWYG editor to setup all parameters during job preparation.

Gerber file import show PCB representation.

Feeder file import is used for feeder assignment.

We are able to import a wide range of PNP files thanks to our flexible import module using profiles for each PNP file type.

Check software BLOG for changes

PNP-Creator V1.05 B296 released!

Our new PNP-Creator job preparation softare is a real WSWYG editor to setup all parameters during job preparation.

Gerber file import show PCB representation.

Feeder file import is used for feeder assignment.

We are able to import a wide range of PNP files thanks to our flexible import module using profiles for each PNP file type.

Check software BLOG for changes

PICKING THE RIGHT (OR WRONG) PICK AND PLACE MACHINE

PICKING THE RIGHT (OR WRONG) PICK AND PLACE MACHINE

https://www.rocketscream.com/blog/2020/07/04/picking-the-right-or-wrong-pick-and-place-machine/

I would like to set the record straight and ask my clients to comment on their experiences.

If everything went good mostly no customer writing about this.

Unfortunately, Lim Phang Mo (Rocketscream) has been experiencing some problems that we are not happy with and are sorry for.

This was an old case from 2018 where we were trying to resolve the issue.

We have sold more than 160 machines with mostly good feedback.

Dissatisfied customers are always not good, but I am glad to read that he is happy with his new solution.

Main board went kaput – The very moment we installed the vibration feeder that comes with the machine, it started to make a loud noise and that is when we knew something was not right. It turns out that the driver of the vibration feeder located on the main board is damaged and is driving the motor on the vibration feeder well beyond it’s maximum rating. SmallSMT told us it was due to the short circuit caused by the vibration feeder metallic body. We find this rather absurd because there was isolation between the vibration feeder electronics and the chassis of the pick and place machine. Anyhow, they sent us a replacement main board albeit it sure looks like a board that has been used before and repaired judging from the amount of flux residue from hand soldering on the new main board.

Sometimes shit happened and our customer produced a short of motor PCB against machine chassis. His message „motor on the vibration feeder well beyond it’s maximum rating“ is totally wrong because the failure of the main board driver caused by shortage. Why does the replaced mainboard work if the motor was the problem??

We have a lot of vibration feeder working under same conditions and received no problems.

Even the actual owner of this machine is operating it without problems.

What is the truth? This was an early machine construction and in a small space there was not enough distance between PCB and machine plate. Under some conditions and without isolation it could cause a short between machine plate. We changed construction and it never happened again.

Even the mainboard received additional fuse in vibration feeder line to prevent these kind of damages

We sent out the spare parts in a short time and after installation everything was ok.

North feeder working inconsistently – A bulk of our time spent on the machine was on configuring the push feeder. It is at best described as “fiddly” and “inconsistent”. It would work perfectly during the setup process, but would then fail to accurately advance the tape of reels during normal operation. This resulted in countless halted job anytime in a pick and place job. But, what baffled us was why it would run almost perfectly on the west feeder but not on the north feeder? We tried every tricks and method suggested by SmallSMT but most of the time it would work fine for a short while before going back to it’s old self. We desperately need the north feeder because there is where our components that comes in 12 mm, 16 mm and 24 mm tape width reels can be installed. Even more shocking, SmallSMT told us the 24 mm feeder is actually not supported! Why sold it to us at the first place?

“what baffled us was why it would run almost perfectly on the west feeder but not on the north feeder”

Really easy to explain that 8mm feeder lines work more reliable using push feeder than wide 12 / 16 / 24mm plastic tapes. Mostly parts heavier so the tape may slide back if top springs not adjusted strong enough to keep a better friction. But it is always comparing apples with pears a CL feeder 12 /16/24mm is a better solution. That is the reason we focussed on these kinds of feeders and added these even to our smallest machine we are selling now. All other machines using drag feeders have the same problems.

North feeder location not accessible by the head – this is one of the most shocking issue we faced on the machine. When we try to move the head to any of the 8 mm tape width feeder on the north side, the software will complain it is not reachable. A solution given by SmallSMT was to shave off a portion of the y-axis limit end stop. We reluctantly shaved off 2 mm from the y-axis limit end stop metal piece. Even though this solved the problem, we start asking our self, isn’t the machine calibrated and tested at the factory to detect such issues? Or it was not even calibrated? After the fix, the top camera will no longer park at the machine origin (indicated by a engraved mark on the machine bed) when the homing function is executed. An offset of 2 mm was also needed on the software to tell the machine everything has been moved by 2 mm on the y-axis.

This was a real issue caused by a manufacturing problem. The machine head could not move back enough caused by a light barrier switch not installed well. After reducing the length of the metal finger moving inside the light barrier switch the machine worked.

We improved our manufacturing process and documented several QE steps by videos since 2018.

So, it should be impossible to receive a machine where not all feeder locations tested anymore.

Reel cover tape snapping way too often – The machine uses a push feeder (instead of a drag feeder) to advance the component reels. A mechanical cover tape peeling mechanism will pull the cover tape towards the back to expose the component to the pick and place head. How tight or lose the tension on the cover tape can be adjusted to one of the 3 settings on the machine. However, even at the least tight setting, the cover tape on our component reels snap way too often. Again, this resulted in countless stop on the pick and place job.

In his case this was our simplest machine he could buy and I told him before he needs a different type of machine but he wanted to buy exactly the simplest one. The funny thing is finally he bought exactly what I introduced a cassette feeder machine.

Push feeder are a much better solution than drag feeder because head is not involved in pulling parts tape. There is no mechanical wear out for the head.

Drag feeder machines use mostly common winder for a feeder bank so all tapes receive mechanical treatment during feeding process if line addressed or not.

Especially this case we tell our customers in any case. So, he knows the limitations of this feeder type. The push feeders are working more reliable than drag feeders and they offer a higher feeder count in smaller space at low price. So, it is ok to accept some limitations.

Some feeder pick up locations are not reachable by the top camera – In order to configure the pick up location, we need to move the head manually to the pick up location without vision assistant. This process needs trial & error and we spent a lot of time here. The vibration feeder is one of the location not accessible by the camera on top of few other push feeders.

This was small machine and push feeder locations on the front side but camera behind the head.

It is logically that we cannot move above the vibration feeder pickup point using the top camera.

And it is not a real problem to use the pickup head to move to this position for teach in.

In retrospect, these first machines are no longer in the program and our current machines are better thought out and adapted to the application of prototype production. Where, in addition to a large number of feeders, high precision is also required.

Compared to the Huawei Guochang machine used, we are miles away from their production quality and are much more innovative too!

We use high-quality imported linear guides and ball screws. The same applies to our servo motors and drivers.

We focus on a wide range of applications, which also requires complex software solutions. The whole process from setting up a project to operating the machine is covered here.

I also believe that an europe based support is an advantage not to be neglected.

We also run a support forum, which none of the other manufacturers mentioned does.

And if you need a modular and durable machine that can also be set up in tight office environments, then you've come to the right place.

Each machine fits through a standard office door and can be placed there without any problems, as there is no need to plan for a machine weight of 200 to 400 kg.

Finally, I can only say that our customers place 0201 and 0.35mm pin pitch components and we know that the machines can do it!

Best regards to Phang Moh I think we are still friends!

ENTRY LINE machines

The VP-2500D-CL22 is a small machine for laboratory use that supports a combination of push feeders and CL feeders. It is the only belt driven machine in our range and can offer a high number of feeders in a small space. The stepper motor drive uses feedback drivers for X and Y axis.

Our VP-2800HP-CL22 is a real good laboratory use machine if high precision needed and bigger working areas need to support bigger PCB or trays.

Last member is the VP-2500HP-CL32 it covers the needs of production use. Cover protect operators and thanks to its big working area and high feeder count.

PREMIUM LINE Pick and Place

All machines have a 3-fold guided Y-axis and a double guided X-axis which allows a very high accuracy even with the size.

X and Y axis are driven by AC servos which allows position feedback via encoders on the spindles.

VP-2800HP-CL62-2H Pick & Place

The VP-2800HP-CL62-2H offers 2 head but already installed 6 slot nozzle changer. It has the same big working area than all of our PREMIUM machines and is the cheapest member of this family.

VP-2800HP-CL64-4H Pick and place machine

Our VP-2800HP-CL64-4H is a cost effective solution if you need more than 100 active feeders and the speed of a 4 head machine. In most of othe machine cases this doesnt speed up placement because of differnt nozzles needed to get installed to each head.

SMALLSMT 19 slot nozzle changer

This prevents an increase in speed as many parts require the smooth nozzle. To take this into account, we have developed the 19 slot nozzle changer which allows up to 4 identical nozzles to be loaded at any one time for better utilisation.

VP-2800HP-CL64-4R

The VP-2800HP-CL64-4R is our racehorse, allowing chip components to be aligned during fly by over bottom camera 1. This machine offers HD cameras allowing to align very small to big parts over same camera at high precision.

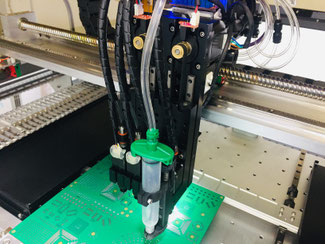

Paste or Glue dispensing option

X and Y axis are driven by AC servos which allows position feedback via encoders on the spindles.

PNP-Creator V1.03 B267 released!

Our new PNP-Creator job preparation softare is a real WSWYG editor to setup all parameters during job preparation.

Gerber file import show PCB representation.

Feeder file import is used for feeder assignment.

We are able to import a wide range of PNP files thanks to our flexible import module using profiles for each PNP file type.

Check software BLOG for changes

Nice customer message from Australia

Hi Sunny,

we have been very happy with our VP-2500HP-CL32. Have never operated a pick and place machine, there has been a slight learning curve, but we have worked out to use the machine and get really good results!

We are very happy about this customer message, mostly if everything is working well nobody talk to us but sometimes it happens :)

Happy Chinese New year to all and keep healthy!