KNOW HOW: Building the workingtable for VP-2500D

I am Michael from SMALLSMT.

I like to show you the work of the past 3 days of installation and mounting my workingtable for the new VP-2500D.

The machine need to assemble our complete PCB product range soon.

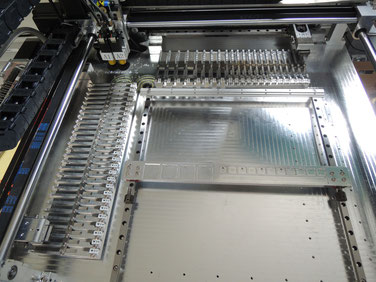

The VP-2500D is a workspace and feeder giant.

My desktop machine provide 27 west side and 21 north side feeder. In my configuration I use 4x 16mm and 4x 12mm feeder lines and all other are 8mm.

Our dual head design allows to use different sized nozzles at one time or the same to improve speed. The strategy allows single head use, automatic double head with same nozzles and finally double head with different nozzle optimization.

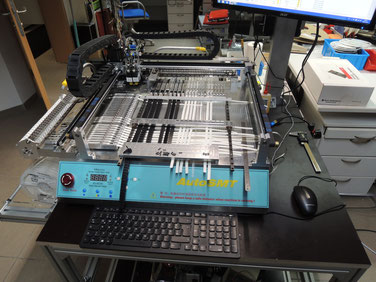

Such a big machine need a stable table construction.

I used a 40mm square aluminium profile based construction and a 20mm table plate. This construction allows easily to add new functions like a reel cart for the feeder.

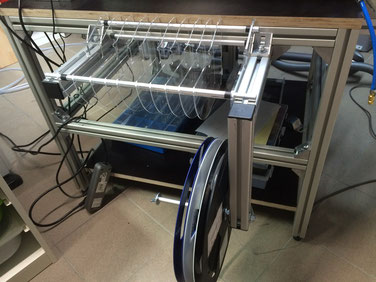

I build a assembly using laser cut acrylic plates and aluminium pipes for the reel cart. The bigger reels need another solution seen on bottom right.

Here you can see the result.

My north feeder cart for big and small reels.

Finally the workspace looks full need to add the last reels.

The machine can handle now 99% of the parts I need for my PCB assembly. We do small production runs up to 500 boards a day.

Write a comment