KNOW HOW: VP-2500D pick and place 0402 test

Hi I am Michael from SMALLSMT and today I like to show you the placement quality and limits of our pick and place machines.

I did some short videos to show the speed and placed some pictures showing the test result for the placement job.

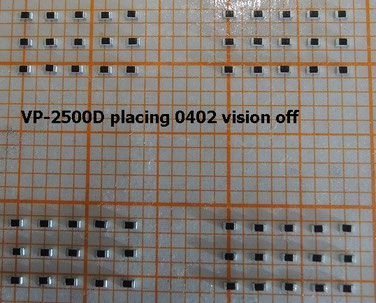

VP-2500D placing a grid of 0402 resistors without using vision

This is the result after placement was running on mid speed.

We see a good result with small offset changes.

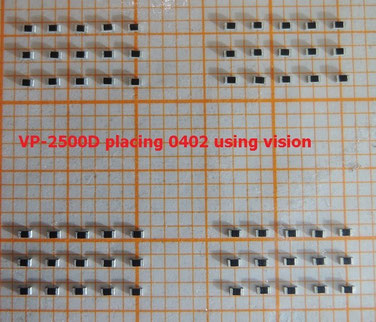

VP-2500D placing a grid of 0402 resistors using vision for offset correction

This is the result after placement was running on mid speed.

The vision system was turned on for offset correction.

We see a better adjusted parts for the position but some small angle errors.

We can improve the results by slowing down the machine but this result is ok because the reflow process will do the rest.

In this demo the machine is running at 2000 parts / hour.

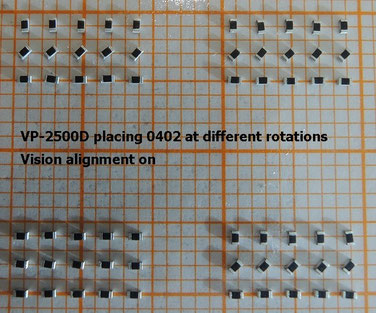

Second placement job using different angles.

The parts where placed at 90, 45, 0 degree.

The vision system was used only for offset correction.

If our machines is almost used for such small parts we can improve the accuracy of vision system be installing a higher optical magnification on one bottom camera.

As a result of this it is possible to use angle correction for 0402 parts too

Write a comment

Alan (Wednesday, 05 August 2015 17:48)

I've been talking with Michael about the 2500, he pulled this together at my request. Needless to say, it pushed me over the edge, order in the works! Very nice work Michael, from all indications, 0402's are easily doable with this machine, both with or without vision. Reflow should straighten any slight mis-alignment. Looking forward to the delivery when it occurs.