- Home

- Home_de

- Products

- Downloads

- Forum

- Sales

- News

- Exhibitions

- Know how

- Building VP-2500D workingtable

- First installation

- VP-2500D 0402 placement test

- Mark detection demo

- Placing TQFP48 demo

- 0201 Placement

- BGA Alignment

- FAQ-Feeder-settings

- Soldering-FAQ

- Controller Upgrade V1 to V2

- How to upgrade to 19 slot nozzle changer

- First setup and placement job

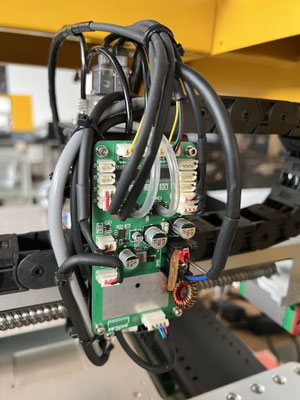

- How to build Electronics

- For Makers

- Questions & Answers

- Software

- Repair Documents

- References

- Service

- Spare-Parts

- Videos

- Warranty

- Kompetenz

- Competence

- Cookie Policy

- Privacy Policy

- About

- PANDA-design-contest

Are you tired of tweezers and magnifying glasses?

Do you want to step up your production?

We have cost effective solutions on our products page.

All machines MODEL 2025 offer 0.01mm X/Y resolution now, V3 controller inside, new pnp head for all 2 head machines offerering CAN controller and pneumatic elements on head. New Top camera for all analog camera machines using USB HD camera module and new light module.

Email:

Send us your inquiry to

contact: sunny@smallsmt.biz for sales questions

contact: michael@smallsmt.biz for technical questions

VisionPlacer are professional pnp machine aimed for prototype and small production.

Our Mission is to make in-house electronics assembly profitable and enjoyable.

We do not only supply a good machine, but we provide THE BEST SERVICE for a long time.

Advantages of the SMALLSMT PNP Machine

- We offer a wide range of pick & place machines which can be used for prototypes and production.

- Many of our customers use their PNP machine to reduce delivery times or to optimise their stock.

- Due to the stock-keeping of the SMT components, variants of the printed circuit boards can be produced just in time.

- Software solutions to support production, machine setup and documentation (PNP-Creator) are our speciality.

SMT ASSEMBLY EQUIPMENT

- From the paste printer to assembly and reflow soldering, optical inspection of the produced assemblies, we offer complete solutions.

Dispensing paste and glue

- All machines can be equipped with a dispensing head to apply paste or glue

- We also realize customized solutions here too.

- Bonding SMT components for double-sided assembly

- We offer an intelligent software (DotMaker) for dispenser dot distribution calculation.

Your steps for a small SMT production

Surface Mount Technology (SMT) is a popular method for producing prototypes of electronic products. SMT production for prototypes can be done in a small scale or in-house, making it cost-effective and efficient for product development. Here are the steps for SMT production for prototypes:

· Design and layout: Create a detailed design of the prototype, including schematics and PCB layout, and verify that it meets the necessary safety and performance standards.

· Component selection: Choose the components that will be used in the prototype, taking into account factors such as cost, availability, and suitability for the application.

· Prototype creation: Use a pick and place machine to place the components onto the PCB, following the design and layout. The components are then soldered onto the PCB using a reflow oven.

· Testing: Test the prototype to ensure that it functions as expected and that all components are securely attached to the PCB.

· Refining the design: If necessary, make any changes to the design based on the results of the testing. Repeat the SMT production and testing process until the prototype is finalized.

· Scaling up production: Once the design is finalized, the SMT production process can be scaled up for mass production.

SMT production for prototypes provides a flexible and cost-effective way to develop and test new products before committing to mass production. It also allows for rapid prototyping, which is important for product development in fast-paced industries.