- Home

- Home_de

- Products

- Downloads

- Forum

- Sales

- News

- Exhibitions

- Know how

- Building VP-2500D workingtable

- First installation

- VP-2500D 0402 placement test

- Mark detection demo

- Placing TQFP48 demo

- 0201 Placement

- BGA Alignment

- FAQ-Feeder-settings

- Soldering-FAQ

- Controller Upgrade V1 to V2

- How to upgrade to 19 slot nozzle changer

- First setup and placement job

- How to build Electronics

- For Makers

- Questions & Answers

- Software

- Repair Documents

- References

- Service

- Spare-Parts

- Videos

- Warranty

- Kompetenz

- Competence

- Cookie Policy

- Privacy Policy

- About

- PANDA-design-contest

Questions & Answers for Vision Placer machines

Q: Why do you use PC system to run the machine?

A: Because the PC system is comfortable to handle for file import, displaying a lot of useful information, and powerful to do the vision algorythms. The user interface is not reduced and it's easy extendable and software upgrades are easy to apply.

Q: What's the language for the user interface?

A: Currently we support English and Chinese but every language is possible because we use "Language files".

If you like to improve translation edit "english.ini" or "german.ini"

Q: How do you support customers?

A: SmallSMT has a network of distributors in several countries (USA, France, Italy, Benelux and others) that provide fast and direct phone support for our

equipment and software. Additionally we have a user forum and email system to support our customers. You will also receive lifetime support for our products directly from SmallSMT. We provide

software updates for you if they become available which keep your machine and system up to date!

Q: What are the PC requirements for your software?

A: You need a Windows 7 system having minimum I3 processor and 4Gb RAM to operate the system. The software is based on DotNet Framework and run on Windows 8 and Windows 10 too.

For Machines using HD Cameras the requirements are:

minimum I5 CPU, 8Gb RAM, Windows 10, one USB3 master port

For machines using V3 controller we need one ethernet port too.

Q: Question on external air. Does it just need a small compressor, or does it require a vacuum pump?

A: You need a small compressor delivering 6Bar 110L/minute intake air, oil free compressed air.

Q: What's the maximum monitor resolution supported by your software?

A: We can use up to 2560x1080 resolution but you need to set scaling factor to 100%. The latest Windows 10 releases allows app based scaling so 4K screens

are no problem now.

Q: How do you prevent the tape crossing problems under the PCB?

A: There is a separator sheet keeping North and West feeder the tapes run on different levels. Some machines have slots to guide the tape under the

machine.

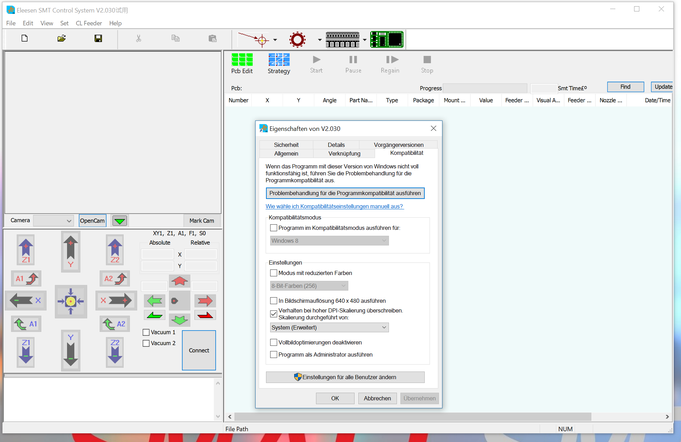

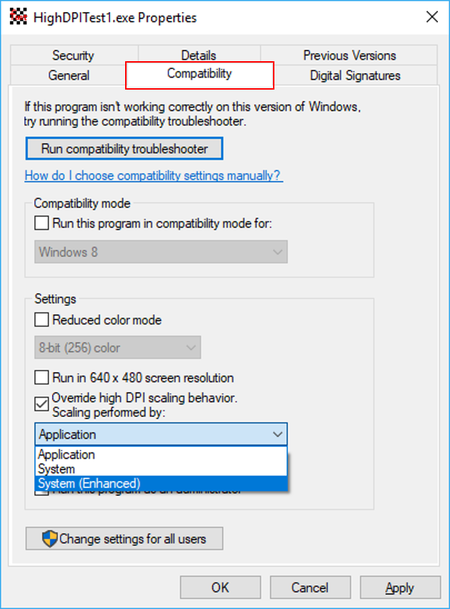

Q: How to repair app scaling problems on high resolution screens?

A: Open application properties in windows app link. Go to compatibility tab and check "Override high DPI scaling behaviour". Then select "System

(enhanced)" from drop down box.

Q: How can I use a 230V servo motor HP machine in the US at 120V AC

A: Use a transformer from Block for example to set up the voltage.

USTE 2500/2x115 http://www.block.eu/en_US/products/transformers/product/393229/