- Home

- Home_de

- Products

- Downloads

- Forum

- Sales

- News

- Exhibitions

- Know how

- Building VP-2500D workingtable

- First installation

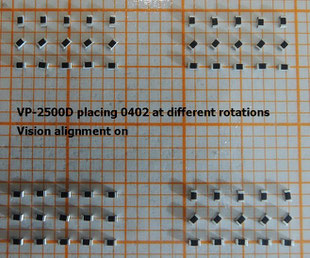

- VP-2500D 0402 placement test

- Mark detection demo

- Placing TQFP48 demo

- 0201 Placement

- BGA Alignment

- FAQ-Feeder-settings

- Soldering-FAQ

- Controller Upgrade V1 to V2

- How to upgrade to 19 slot nozzle changer

- First setup and placement job

- How to build Electronics

- For Makers

- Questions & Answers

- Software

- Repair Documents

- References

- Service

- Spare-Parts

- Videos

- Warranty

- Kompetenz

- Competence

- Cookie Policy

- Privacy Policy

- About

- PANDA-design-contest

How do I know a VisionPlacer is right for me?

You will never find us trying to push our product to a customer that it doesn’t make sense for. You are welcome to reach out to us send email to explain your use-case, and we are more than happy to advise on whether VisionPlacer is right for you. If it is not we will happily suggest something that is more appropriate!

We’re proud of this approach and are happy to say it is being well received and appreciated by our community and the individuals we've spoken to thus far.

How to select the right PNP machine

A belt machine need calibration if temperature change and over operation time (belt tension changes).

If no position feed back system used the precision of this kind machines is ok for >=0.5mm pin pitch and down to 0402 placement.

Another point if you use round rail linear guides you receive additional vibrations and head shaking because structure is not as strong as profile rail linear guide systems we use.

Profile rail linear guide systems have more rigidity and precision.

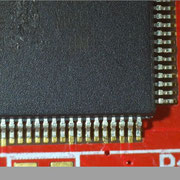

The ball screw machine need only single time calibration and position is stable over long time. Our HIWIN ball screws receive +/-0.03mm precision over 300mm distance.

Over all precision for our HP machines is about +/-0.05mm.

The placement speed for belt and ball screw machine is equal because it depend on physical limits. You can't use higher speed without loosing precision.

VP2000S / VP2500D

- Round rail guides

- Belt machine need slower acceleration and break curve because belt is working like a spring when head stops.

- The head shaking when movement stops will decrease precision or you need to use slow Z axis speed.

- belt tension changes over time and temperature changes and will influence the final position

- Placement precision good from 0603 to 24x24mm >=0.65mm pin pitch

VP-2500DP / VP-2500DP-CL16 / VP-2500DP-CL32

- Profile rail linear guide system from HIWIN

- Belt machine has closed loop stepper driver but belt tension will influence the final position so we don't have absolute position.

- belt tension changes over time and temperature changes and will influence the final position

- Placement precision good from 0402 to 24x24mm >=0.5mm pin pitch

VP-2500HP / VP-2800HP / VP-2800HP-CL22 / VP-2500HP-CL32 / VP-2800HP-CL64-4H / VP-2800HP-CL62-2H

- Ball screw spindle (HIWIN)

- Profile rail linear guide system from HIWIN

- Machine has no head shaking because immediately stops on position only the servo motor regulation may need a short time to stabilize.

- Machine uses encoder AC servo motors and are mounted directly to the spindle. We receive absolute position at high precision.

- Placement precision good from 0201 to 30x30mm >=0.40mm pin pitch

Finally the combination of profile rail linear guide systems plus ball screw spindles using AC servo motor drive with encoders receive the best precision. >> HP machine

For Z axis precision we use a linear belt drive instead of a simple spring and rocker arm system.

0201 parts placement

BGA Alignment

BGA 0.8mm pitch Alignment using vision system using camera 2

Using a VP-2500D belt driven machine!

Feeder settings FAQ

TQFP100 Fine pitch placement using HP machine

TQFP 100 placement result using VP-2800HP machine. Result of previous video. Same accuracy on all of our ball screw spindle HP machines. #smallsmt pic.twitter.com/5yg1KsyIhn

— SMALLSMT (@SMALLSMT) 24. Januar 2018

TQFP 100 0.5mm pitch placed using a VP-2800HP machine #smallsmt pic.twitter.com/MO49Jawyta

— SMALLSMT (@SMALLSMT) 24. Januar 2018

A Guide to effective stencil design

Interesting website showing the common rules for stencil design.

http://www.surfacemountprocess.com/a-guide-to-effective-stencil-design.html

And for all SMT related information http://www.surfacemountprocess.com/