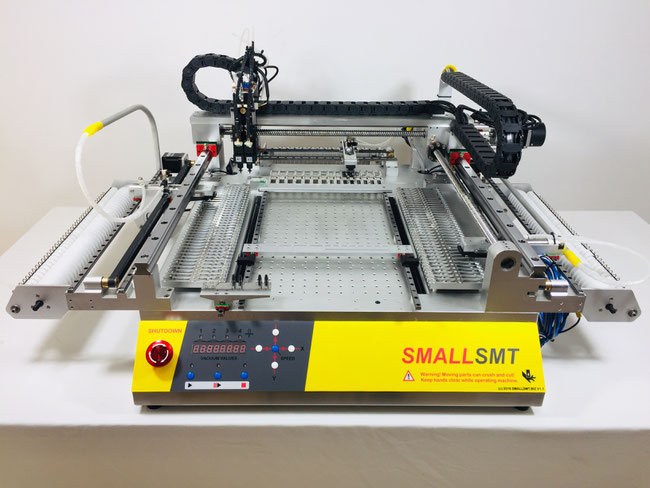

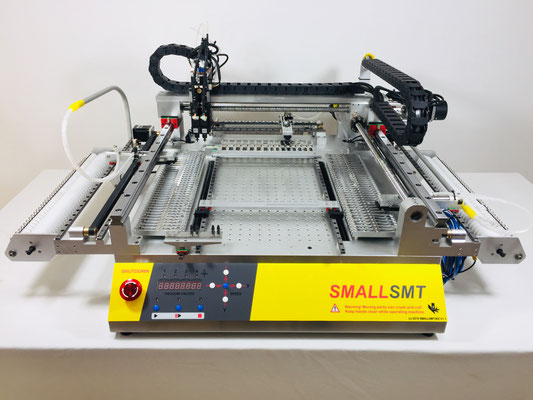

VP-2800HP High Precision PNP machine

VP-2800HP the high precision machine for prototype assembly.

All push feeders are included in the price and can be extended with dispensers and vibrating feeders for maximum flexibility!

- linear guides on all axis, no head shaking like competitor machines using small belts and simple round rods

- winder mechanics on our integrated push feeders

- 3 side feeder possible having slots to move wasted tape under the machine

- 2 bottom cameras one top camera for measurements and mark detection

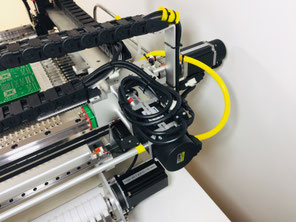

- AC servo motors for X and Y axis directly coupled to HIWIN ball screw spindles.

- Closed loop position control using optical encoders inside the AC servos.

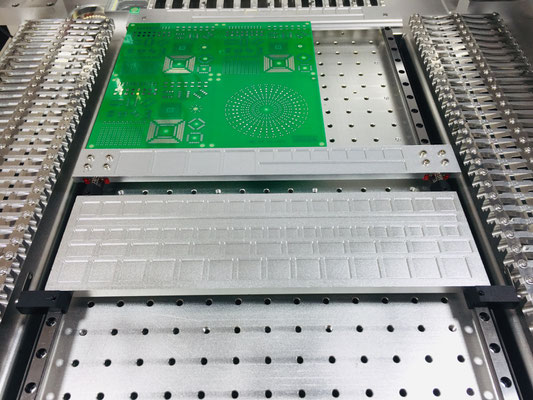

- small tray feeder included on north and south side of PCB holder

DATASHEET

Motion system

AC servo motors on X and Y axis using optical encoders resolution 0,02mm.

Stepper motors for Z axis and A1 + A2.

Angle resolution 0,0278 degree 1/6400

Mechanics

Linear guides from HIWIN in X / Y / Z axis.

Linear guides on each push feeder side.

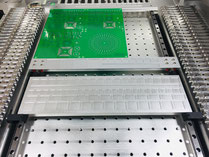

Working area: 300x 370mm NW and 250 x 370mm NWE

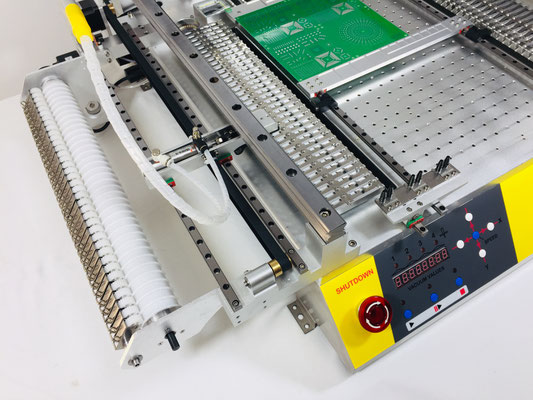

STRIP FEEDER

VP-2500DP Strip feeder assembly including

9x 8mm, 7x 12mm, 2x 16mm feeder lines.

It's possible to do a customized part too!

VIDEOS

VP-2500HP and VP-2800HP are similar machines only differs in size.

Vision Placer VP-2800HP

This machine has 2 heads and up to 93 Feeders

New! X and Y axis have ball screw spindle linear guides and servo motors high precision machine!

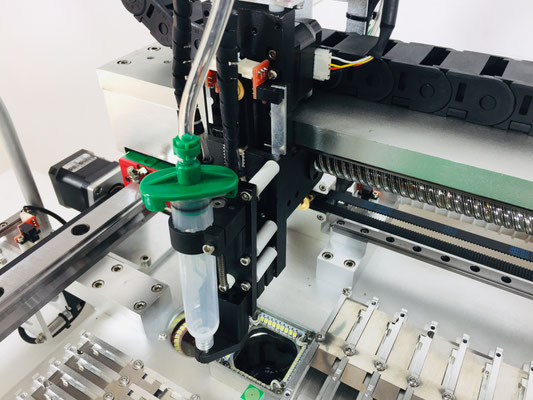

VP-2800HP dual head 360 degrees continuous rotation, (gallery)

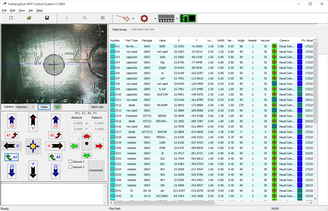

1x top and 2x bottom cameras have a different optical magnification,

nozzle changer included!

up to 60 x 8mm feeders plus build in tray option plus 34 x8mm optional east feeder lines,

WEST feeder 34 x 8mm lines,

NORTH feeder custom 13x 8mm + 4x 12mm + 4x 16mm as a sample configuration, or 25x 8mm,

EAST feeder 34 x 8mm lines,

the west feeder is standard North feeder optional,

Pneumatic push feeder design the head don't need to wait for pickup because of tape dragging is processed in advance.

250 x 370mm working area, Z axis travel height is 15mm maximum part height 12mm,

capable to mount 0201,0402,0603,0805,1206 and bigger, SOP, QFN, TQFP with minimum 0,35mm pitch,

machine steering keyboard for run / pause / stop and axis movement,

vacuum display for each placement head,

CP45 nozzles snap in holder,

3 nozzles included 2x CN065 + 1x CN220,

Placement speed above 3600pcs / hour!

Mains supply is 110V / 230V AC 50 / 60Hz 400W

X axis 200W LEETRO Servo motor

Y axis 400W LEETRO Servo motor

32 Bit ARM build in controller system connected to PC by USB interface.

Shipping is done by DHL Express Air freight!

$9,990.00

Final price excl. shipping costs

Free shipping to the following countries: Show more Show less

- 90 kg

- Available

- Delivery in 4-6 weeks1