- Home

- Home_de

- Products

- Downloads

- Forum

- Sales

- News

- Exhibitions

- Know how

- Building VP-2500D workingtable

- First installation

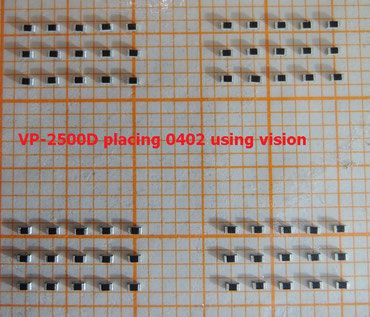

- VP-2500D 0402 placement test

- Mark detection demo

- Placing TQFP48 demo

- 0201 Placement

- BGA Alignment

- FAQ-Feeder-settings

- Soldering-FAQ

- Controller Upgrade V1 to V2

- How to upgrade to 19 slot nozzle changer

- First setup and placement job

- How to build Electronics

- For Makers

- Questions & Answers

- Software

- Repair Documents

- References

- Service

- Spare-Parts

- Videos

- Warranty

- Kompetenz

- Competence

- Cookie Policy

- Privacy Policy

- About

- PANDA-design-contest

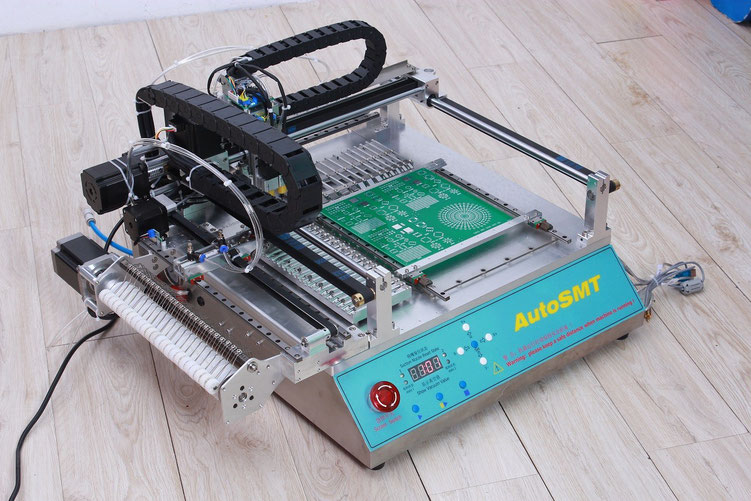

Vision Placer VP-2000D and VP-2500D pick and place machine introduction

Flexible solution

You need a short time solution for your PCB assembly?

No problem with our pnp machines VP-2000D and VP-2500D you can complete your prototyping job in a very short cycle!

Fast Prototyping

No more boring manual SMD place jobs taking hours to complete!

Easy to reproduce your prototypes.

High placement quality and possibly no wrong parts in placement.

And finally no long time waiting for external manufacturers.

Best value for the price

Vision Placer pick & place machines will pay off quickly because you save a lot of time and external manufacturing costs!

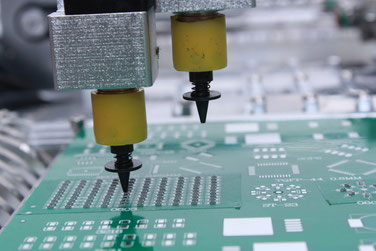

High performance and flexible head concept

The use of two pick and place heads give you the choice to select between 3 placement strategys:

- SIngle head placement using two different nozzles mostly no nozzle change necessary.

- Double head placement using same nozzles is used to increase the placement speed you take 2 parts and place.

- Double head placement using different nozzles the software optimizes the access cycles and try to pick two different parts together.

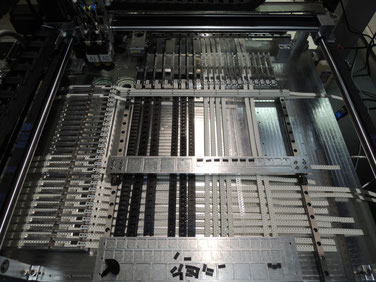

No hidden costs for feeder systems

You receive a fully working system no need to buy feeder by feeder.

We reduced the number of mechanical parts so it's easy maintable and have less spare part costs!

The pneumetic push feeder on West and North side pushes the tapes in advance before the nozzle picks the part.

It is highly adjustable you can set the force by changing the applied air pressure, adjust the damper system and regulate the air flowrate in the pneumatic cylinders.

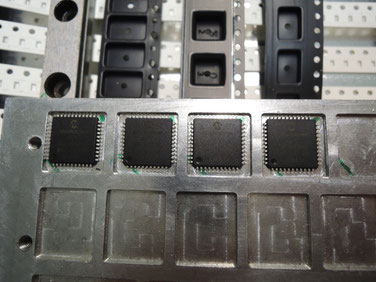

We have a small tray feeder integrated in PCB holder and optional tray feeder to add in the working area.

All pick up positions are software defined and you can add unlimited number of software feeders.

Integrated "little" tray feeder in pcb holder tray.

You need to take care of the different positions because of various PCB sizes.

Compatible and functional

Our Vision placer pnp machine can process SMD components from standard reels, cut tapes, and trays.

The software can define pick up points, lines and grids at any place inside the working area.

Custom feeders and external vibration feeder can be easy integrated

Precise and fast placement

Because of it's fast vision alignment system it is possible to align every part even resistors and capacitors and receive 2000 components per hour placement speed.

Two alignment strategies are availiable:

- Offset alignment including angle correction

- Only offset alignment for chips

The vision system is adjustable for speed or precision in several steps and you can set the repeat step count.

Good investment for the future

We provide software updates for our PC based Vision Placer software free of charge.

You will receive improvements and additional functions when availiable.

Our current software is working on Windows 7 up to Windows 10.

You need an I3 PC having 4Gb RAM to run the software.

The UI language is English and Chinese.

Pick and place data can be imported in the following formats:

- Altium Designer

- Protel 99SE

- Power PCB

- Allegro

- Excel CSV

- HTML

- Cadsoft Eagle Partlist support in beta phase!

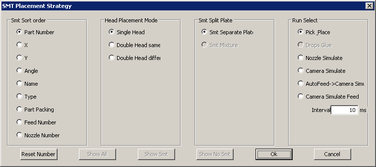

Various placement strategies

You have options to select various placement strategies,

select the mounting mode and to run different simulations:

- Nozzle simulate

- Camera simulate

- combined modes operating the feeder too

- different sorting options

VP-2000D vs VP-2500D comparsion

| We show only the differences! |

VP-2000D |

VP-2500D |

|

Workspace Area |

240 x 270mm | 360 x 320mm |

| West Feeder (standard) | 21 x 8mm | 26 x 8mm |

| North Feeder (optional can be customized) | 15 x 8mm | 25 x 8mm |

| Weight | 45Kg | 55Kg |

| Z Axis travel limit / maximal Component Height | 15mm / 12mm | |

| Position accuracy / resolution | +/- 0.025mm ( 0.001") | |

| Vision System | 3 Cameras , 1x Top, 2x Bottom Cameras | |

| Vision Alignment Limits |

Parts from 0402 to 20 x 20mm, >= 0.4mm Pitch |

|

| Fiducial / Mark recognition |

>= 1mm round or square pad offset and angle correction |

|

| Visual alignment modes | XYA = offset + angle, XY = offset correction only | |

| Nozzle Type |

Samsung CP45, snap in holder changeable by hand |

|

|

Vacuum generation inside needs |

Compressed air 6 Bar 110L/min oil free! |

|

| Controller System |

PC based Vision System and local 32 Bit Machine Controller System,

modular stepper driver, 480W switched power supply 110 / 230V (50 to 60Hz) |

|

| Mechanical guidings |

2x 12mm X-Axis, 2x 10mm Y-Axis |

|

|

Placement speed |

<= 2000 parts / hour at mid speed using full vision single head <= 3600 parts / hour at mid speed using double head operation > 4000 parts / hour at high speed needs fine tuning |

|

North feeder setup examples

|

VP-2000D |

VP-2500D |

|

| standard 1 | 1x 24mm 2x 16mm 6x 12mm 5x 8mm | 2x 24mm 3x 16mm 6x 12mm 7x 8mm |

| standard 2 | 16x 8mm | 25x 8mm |

| custom 1 | 2x 16mm 4x 12mm 7x 8mm |

1x 16mm 4x 12mm 18x 8mm |

| custom 2 | 1x 24mm 2x 16mm 5x 12mm 4x 8mm |

1x 16mm 5x12mm 16x 8mm |

| custom 3 |

4x 16mm 4x 12mm 13x 8mm |

|

| recommend configuration |